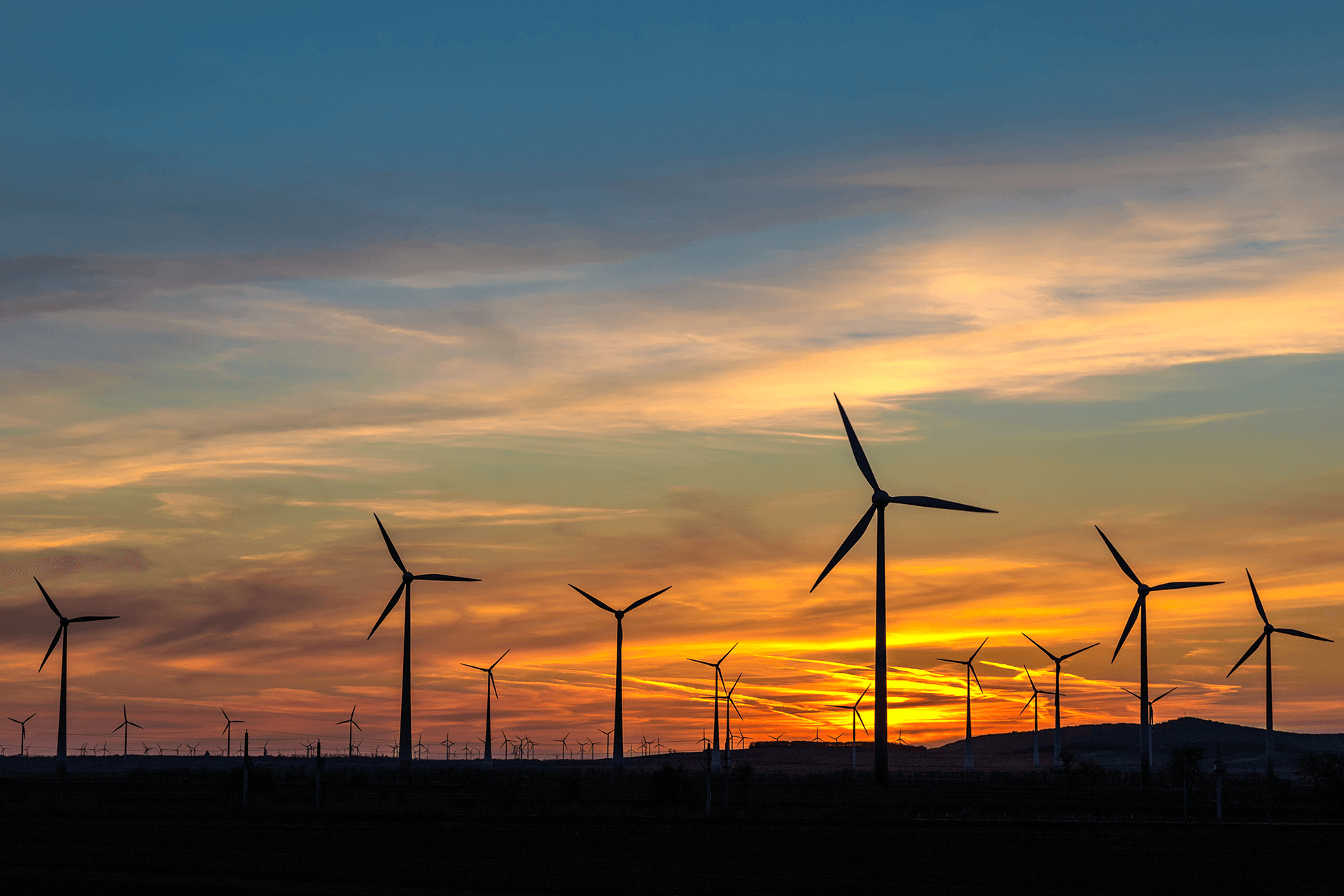

Wind Turbines

Monitor wind turbine performance in real time and predict reliability issues without the need for expensive service intervention

Contact usAvoid failure and maximize uptime

Optimize reliability and output

Minimize costly service interventions

Reduce operating costs

Wind Turbines

Asset Challenges

- Maximizing uptime and productivity

- Measuring machine performance remotely

- Component wear and damage

- Shaft misalignment and mechanical imbalance

- Avoiding unscheduled maintenance

- Efficiency optimization

- Minimizing running costs

Solution

Elmodis Solution

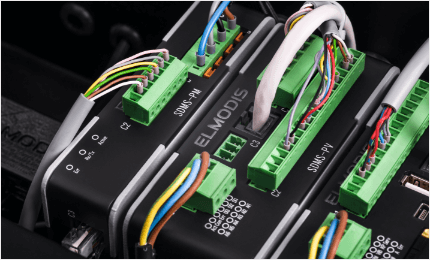

Unique hardware + software solution

Smart edge devices use local data and machine learning algorithms to provide instant performance insights

Cloud or on premises software platform enhances analysis and provides a broad operating picture

Qualitative data

24/7, 365 days a year

Reports, alerts and insights via SMS, email, web interface or clients own systems

Flow and other parameters calculated without the need for specific instruments

Outcome

Optimal outcome

INCREASED OVERALL OPERATIONAL PRODUCTIVITY

Your entire operation works more effectively when assets perform as expected.

REDUCED ASSET ENERGY CONSUMPTION

Energy is typically one of the highest operational costs. Even a small % reduction can make a big difference overall.

INCREASED ASSET LIFETIME

Critical assets are expensive. Total asset lifecycle analysis and operation can help you to procure and operate better.

REDUCED MAINTENANCE COSTS

Predictive insights into your assets’ operational condition enables effective planning and efficient maintenance operations.

NO SURPRISES

Unplanned asset downtime can seriously impact your whole operation affecting productivity, expenses and safety. Avoid this by eliminating downtime altogether.

Cost

Easy and low cost integration

Integrating the Elmodis solution on your site is straightforward and low cost, usually taking no more than an hour per machine. We provide comprehensive support throughout.

Return

Return on Investment

In many cases, your annual savings through efficiency improvement and maintenance cost reduction should exceed your year one investment and you will enjoy savings every year.

Elmodis will provide you with a projection of potential savings based on the operating data you provide us. Even smaller assets can benefit from the Elmodis solution, and provide a healthy return on investment.

Contact UsWant to know more about our technology?

Request a Demo

Case Study

Name of case study

This section will be uploaded shortly.

+20%

effect description

3x

less risk of failure

Clients

They trust us

For Xylem clients, operating critical assets and water systems, reliability at optimized total life cycle cost is a top priority. For decades conventional technologies has been used and many solution providers have been promising the “silver bullet” for predictive maintenance. We learned overtime that predicting potential failures is simply not good enough.

Partnering with Elmodis does provide Xylem the enabling technologies that makes optimization of any rotating asset possible. Our combined solution is not just to monitor in real time asset condition, able to predict potential failures. SAM PRO provide the digital twin of Xylem Subject Matter Expertise and Elmodis edge technology for automated prescriptive insights.

Mike W. Otten

Director Systems Intelligence