Outcomes

Optimize asset efficiency and reliability, maximize uptime, reduce operating costs, banish surprises

Contact usAsset Reliability

System Features

Process Implementation

Outcomes

Asset Reliablity

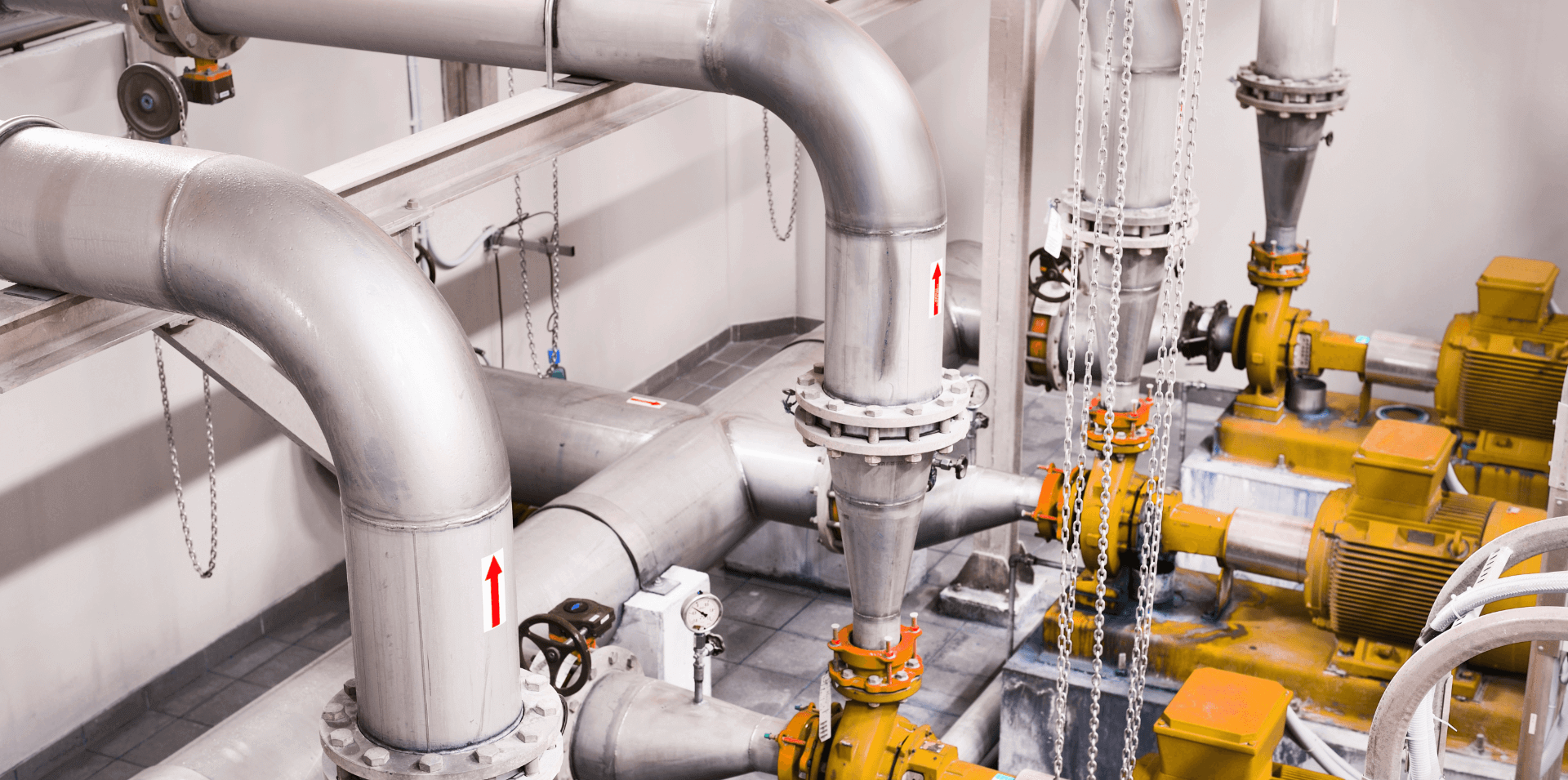

Evolving maintenance practices have improved asset management effectiveness in recent years and now our technology can provide operators with real-time insights into asset performance and advanced warning of potential problems before damage is caused or breakdowns occur.

Outcomes

Asset Performance

A reliable asset is critical to overall system uptime just as operating efficiency is also vital in ensuring that design process conditions are met and running costs are optimized. It is not uncommon for process demands to change over time and the Elmodis system enables operators to easily identify when assets are operating outside their best efficiency zone and to take corrective action. These improvements usually limit wear, increase asset lifetime and reduce energy consumption, providing significant recurring savings.

Outcomes

System Features

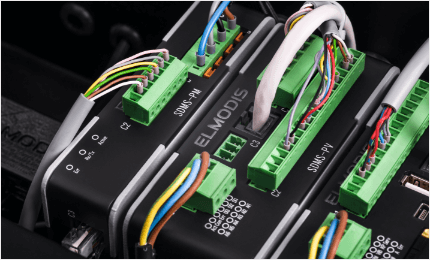

ASSET MONITORING

Annual Service subscription, including system features and functionality:

- detection of a process change, overloads,

- statistical data – number of starts, operation time,

- detection of phase failure, asymmetry,

- overview of parameters measured in continuous online mode.

ASSET DIAGNOSTICS

Features as for MONITORING package plus additional functionality:

- detection of misalignment,

- detection of imbalance of the motor rotor,

- diagnosis of motor electrical condition,

- detection of anomalies,

- tracking parameter trends.

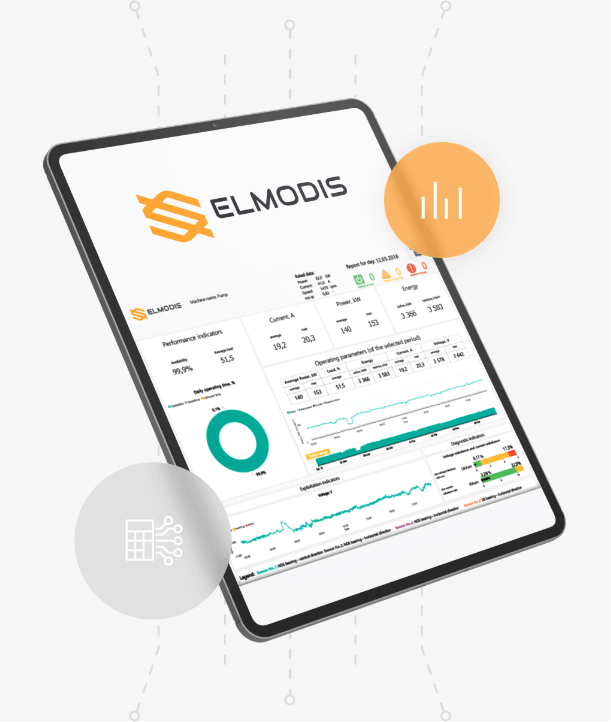

ASSET PERFORMANCE

Features as for DIAGNOSTIC package plus additional functionality:

- benchmark reporting for operating parameters of all monitored assets to enable abnormalities to be recognised more quickly,

- overview of measured parameters in continuous online mode,

- notification when warning and alarm limits are exceeded,

- operational conditions regarding RPM, Best Efficiency Point,

- operational problems e.g. Cavitation and Dry Run.

Want to know more about our technology?

Request a Demo