Solution

Elmodis, your assets’ perfect partner for ensuring health, long life and wealth through savings

Contact usHow it works

X-as-a-Service

Process Implementation

Technology

How it works?

Elmodis provides a hybrid solution: hardware and digital services providing comprehensive monitoring and diagnostics for industrial machines, resulting in improved reliability and efficiency. With its optimum architecture, the solution is fully scalable and adaptable and is easy to implement for any number and any type of electrically-driven machine.

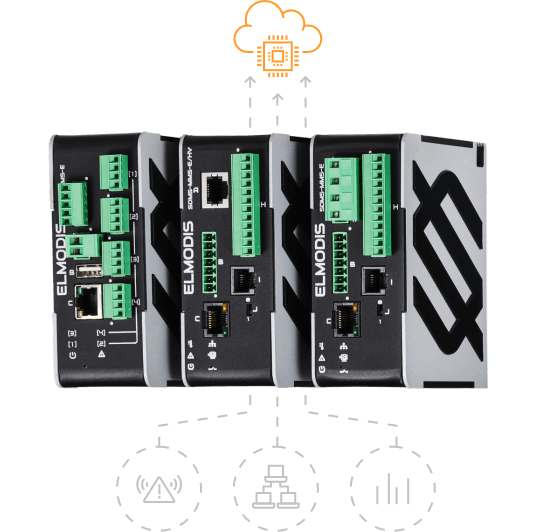

Compact smart Edge devices read electrical signals from assets together with other local data and perform thousands of informed calculations per second, before transmitting resulting KPIs to the Cloud for further processing. Operators view asset performance insights via the secure web portal and alerts can be sent direct to operators if urgent intervention is required.

01 / 04

Hardware

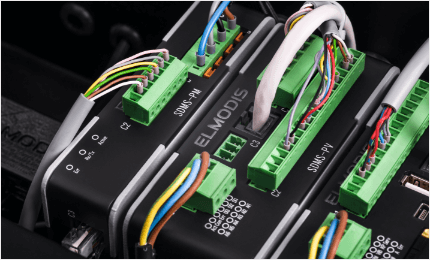

Elmodis diagnostic and monitoring modules are installed either in the existing motor control center panel or in a compact dedicated local panel. Connection to the motor cabling is performed without interfering with the wiring system of the asset. Measurements are performed at very high frequency, which enables ultra-high resolution diagnostics to be performed, e.g. detecting minute dynamic irregularities in electrical signature directly relating to machine operation. KPIs are developed within the diagnostic module, using patented machine learning backed algorithms. Additional diagnostic and monitoring modules enable integration of vibration sensors and selected process parameters (temperature, pressure, flow rate, etc.), if necessary.

The Elmodis solution is fully scalable – new diagnostic and monitoring modules can easily be added without needing to reconstruct or implement the entire system from scratch.

Quick installation

Qualitatve

data

Artificial Intelligence

02 / 04

Connectivity

Interconnected diagnostic and monitoring modules send preprocessed data (KPIs) to the computing cloud.

Edge computing (processing at the machine) enables huge amounts of data to be preprocessed and compressed into high quality quality KPIs should be free from interference and contain only the vital operating parameters of a machine. This process significantly reduces transmission time and cost. Processing and transfer are performed in real-time so users are able to see operational insights in real-time also.

Data transmission is possible via Cellular network, Wi-Fi or Ethernet so the Elmodis solution can be successfully implemented, even in remote locations with no fixed communication infrastructure.

03 / 04

Cloud & platform

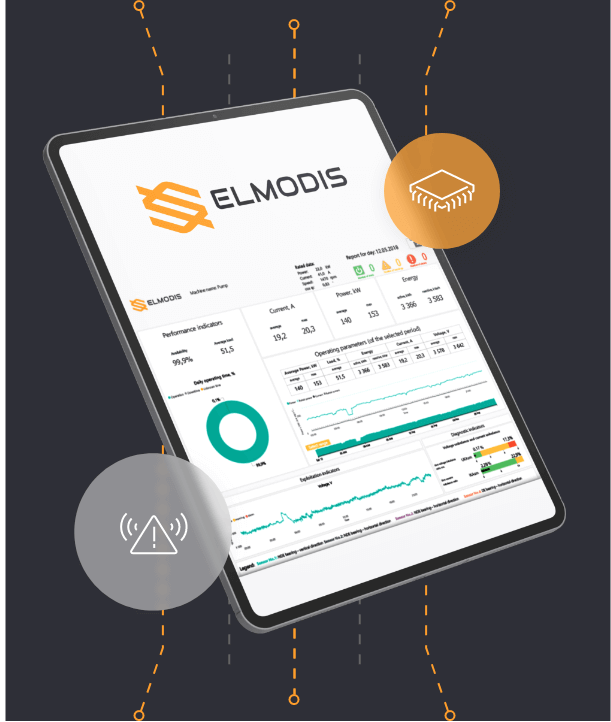

Data and reports are stored in the Elmodis secure cloud server. Users access the server through a secure portal with cyber-secure protected login, have permanent access to all information on their registered, machines and can view all archived data and reports. The data is encrypted and protected against unauthorized access. It is also possible to personalize reports according to the needs and/or authorization granted to a particular user. The user has no software to buy or maintain. The digital services subscription covers all user needs, including maintenance of the master software platform, so operators have the comfort of knowing that they always have access to the latest software version.

Current system updates

Secure data

Personalized reports

04 / 04

Analytics and reporting

With the patented Elmodis method of electrical signal analysis, it is possible to detect irregularities in the operation of an industrial machine. Data is processed in the cloud-based on machine learning algorithms and virtual process and measurement models, dedicated to different types of machines (e.g. pumps, fans, conveyors, turbines, etc.) The machine learning algorithms make each new dataset that then improves the analytical model, and this, in turn, translates into more efficient prediction (anticipation of possible failures) and analysis of the machine condition.

Thanks to the analysis and comparison of data from multiple monitored devices (e.g. many fan-driving motors of the same class) the prediction efficiency levels are increased iteratively.

Machine learning

Fast scalability

Online view

X-as-a-Service

Elmodis provides

1. ASSET MONITORING AS A SERVICE:

- detection of a process change, overloads, etc.

- statistical data – number of starts, operation time,

- detection of electrical parameters malfunctions,

- overview of parameters measured in continuous online mode,

- notifications (warning and alarm and any events).

2. ASSET DIAGNOSTICS AND CONDITION PREDICTION AS A SERVICE

ADDITIONALLY:

- detection of power supply abnormalities,

- failures detection (misalignment, imbalance, etc),

- diagnosis of motor electrical condition,

- detection of anomalies,

- tracking parameter trends.

3. ASSET PERFORMANCE OPTIMIZATION

AS A SERVICE

ADDITIONALLY:

- benchmark reporting for operating parameters of all monitored assets to enable abnormalities to be recognised more quickly,

- overview of measured parameters in continuous online mode,

- machine and process notifications (warning and alarm and any events),

- operational conditions,

- operational problems.